Battery capacitor industry

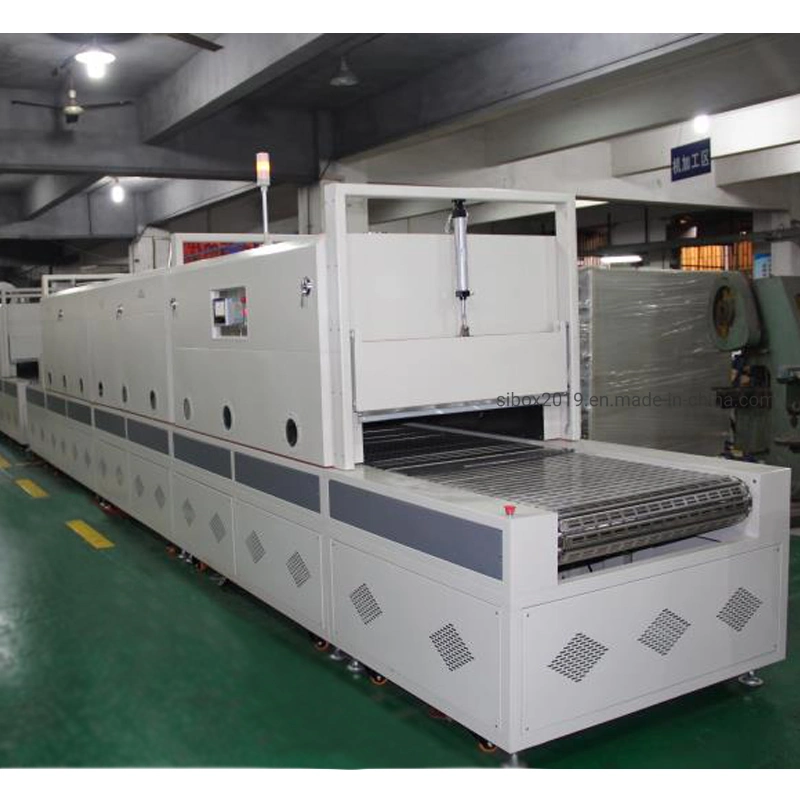

Inner size:L600mm*H150mm*W800mm

Outer size:L24000mm*H2560mm*1400mm

Conveyor height:850mm* ±50mm

Independent unit size:L2000mm*H2560mm*1400mm

Heating mode:Electric

Temp range:Room Temp+100ºC

Temp homogeneity:≤ ±3ºC

Speed of conveyance:5-10m/min

1 Material size and weight :Length 932mm (Conveyor line width direction ),Width 222mm (Conveying direction of transmission line ),Height 163mm (open height),Single 120kg;Six in batches,Intermittent step transport (manual control);Material: carbon steel

2 Temperature zone separation: the feeding port of the constant temperature heating section is hot to use the automatic rising and lowering partition; a constant-temperature heating section and an automatic lifting and heat-insulating door are used for the material receiving opening of the cooling and cooling section, and an automatic lifting and heat-insulating door is shared; and an automatic lifting and heat-insulating door is used for cooling the discharging port of the cooling section;

3 Heating temperature range: room temperature-100 ºC adjustable, setting 2 constant temperature heating zones (Temperature detection and display, unified setting, independent temperature control, respectively)

4 Cooling temperature range: room temperature-35 ºC, 1 cooling range (Temperature detection and display )

5 Temperature record: constant temperature heating section contains 6 temperature detection points (front, middle, rear and both sides ),record temperature detection data,detection frequency adjustable (0-60min).

6 Equipment direction: facing to the operating surface, right hand in and out of the left.

7 Continuous working time: continuous working time greater than or equal to 120h.

Characteristics of the equipment

1,Design according to the proportion of human engineering, easy operation, modern appearance.

2,Argon Arc full Welding of all stainless Steel in Inner to prevent dust from the machine itself.

3,Unique air-duct design to ensure the temperature inside is uniformity

4,First-class technology of heat &thermal insulation, sealing effect is excellent.

5,Double over-temperature protection, safer and more reliable.

6,Heating up fast, and the temperature is stable and accurate.

7,The shell temperature is low, which has little effect on the indoor environment temperature.

8,According to the product set up a variety of heating and air mode, energy saving, safety and environmental protection.

9,Module design:Each section manipulation and operation in flexible independently can be available.

10,Colors can be customized base on color card.

| Technical Parameters of Industrial Oven | |||||

| Type | Common | Clean | Finishing Cure | Explosion-Proof | Vacuum |

| Temperature range | 0-250ºC | 0-350ºC | 0-550ºC | 0-700ºC | 700ºC |

| Temperature Homogeneity | ±1ºC | ±3ºC | ±5ºC | ±1.5%ºC | |

| Heating Rate | <=5ºC/min | <=8ºC/min | <=10ºC/min | 10ºC/min | |

| Energy Type | electrical | Gas | Steam | Air Energy | Other |

| Heating Mode | Electric | Infrared | Other | ||

| Chamber | Single | Twin | Three | Other | |

| Sheathing Material | Cold Drawing Spray-Paint | Stainless S teel | Other | ||

| Chamber Material | Stainless S teel 201 | Stainless S teel 304 | Galvanized Sheet | Other | |

| Heat Insulating Material | Aluminosilicate Rock Wool | Insulating Fibre-Board | Firebrick | Other | |

| Air Transport Mode | Left and Right | Up and Down | Front and Behind | Symmetrical Left and Right | |

| Air Motor Position | Top | bottom | Hindside | Sidepiece | Other |

| Number of Explosion-proof Doors | One | Two | Other | ||

| Manual door | Single Door | Double Door | Three Doors | Other | |

| Automatic Door | Revolution door | Side Sliding Door | Lift door | Roll-Up Door | Other |

| Cart Type | Double-Deck Cart | Motor-Trolley | Landing Cart | Automatic Trolley | Other |

| Power Control | SSR | SCR | Other | ||

| Control Mode | Instrument Control | HMI Control | Network Control | Other | |

| Timing Mode | Manual | Automatic | Other | ||

| Safety Protection Function | Overtemperature | Overload | Phase Sequence | Earth Leakage Protection | Other |

| Detection Function | Temperature | Thickness | Flame | Pressure | Other |

Graphic wind circulation:

|  |  |  |

| Single-sided supply air type | Double-face type | Double-face blast with explosion-proof | Thermal rising type |

|  |  | |

| Thermal rising type | Thermal radiation type | Hot air radiation | Hot air radiation |